1. Introduction

The environmental impacts of livestock systems have become an important issue of public and scientific debate worldwide, for more than a decade1. Global challenges from sdgs (Sustainable Development Goals2) lead to the need to produce more food from less resources with less environmental impacts. In this sense, livestock production has a very important role to provide sustainable food to humanity, considering the projected increase in world population. However, currently the subject that arouses greater interest and international debate is limiting the use of natural resources, under the statement that more efficient production can reduce impacts on climate change and other environmental impacts3.

Uruguay’s cattle sector is a critical component of Uruguay’s agricultural sector, responsible for approximately half of its agricultural gross domestic product (gdp), which is 8-9% of the national gdp4. Moreover, for a country of just 3.4 million people, it supplies 5% of the beef on the global market (in terms of weight), making up 20% of the total value of Uruguay’s exports ($1.5 billion)4. In addition to its economic and social importance, Uruguayan cattle systems are managed under free-range systems with a low degree of intensification, where natural pastures are the main feed resource for cattle. However, this sector has a significant environmental footprint5)(6)(7)(8. In the last two decades these systems have needed to incorporate other technologies (supplementation, introduced pasture, etc.) to increase production or improve efficiency and keep competitiveness. This transition toward more complex and intensive systems may lead to different states of degradation of natural resources.

In many agricultural countries such as New Zealand, Canada and Ireland, where cattle are an important production system, the impacts of intensification on the environment is a common concern. To address this problem, the assessment and quantification of environmental emissions have become important to determine their impacts and to understand the potential benefits of mitigation options. Currently, there are some practical models that can be used in livestock production, such as Overseer in New Zealand9 and Holos in Canada10, which are based on biophysical models to evaluate changes in production and estimate environmental emissions. However, this limited number of applied environmental models are based on productive, high quality pasture/crop-feed systems with relatively high inputs. In contrast, cattle and sheep production in Uruguay is largely associated with extensive grazing systems on unique natural grassland systems of relatively poor feed quality and often with no nutrient inputs in fertilizers. Thus, there is a need for a model that can take account of these systems and that brings together country-specific data to provide information of relevance for Uruguay.

In summary, there is a need for a tailored environmental tool for Uruguay that should: identify “hot-spots” of resource use and environmental emissions, translate information into useful and practical recommendations, account for changes over time, test management/mitigation options, and enable avoidance of “trade-offs” between impacts when assessing future options. This paper gives an overview of why a national model for cattle systems is needed and the specification of a complete animal biology model with modules for estimating resource use and environmental emissions. It includes the variables, equations and parameter values that are used in the tool, the validation of this model with international models, and illustrates how it works using a case study. Finally, a description is given of the features that make this tool suitable as a decision support tool for Uruguayan conditions.

2. Materials and methods

2.1 Principles of emag development and construction

The cattle and sheep environmental assessment, emag (Evaluación Medio Ambiental Ganadera, in Spanish), is a decision support tool that allows simulation of the environmental performance of cattle and sheep systems, accounting for the complexity of the national systems and diverse use and inputs. The emag model was developed within the framework of the Uruguayan Family Farm Improvement Project uffip (http://www.uffip.uy/) with the objective of evaluating resource use and environmental emissions from livestock systems that would be a useful support to improve knowledge of producers and technicians, as well as to enable them to understand the effects of potential changes to their systems and create awareness of the importance of environmental aspects. To illustrate the usefulness of emag, a case study of a cattle and sheep system from the uffip project is presented on section 3.1. This model meets the current methodology requirements according to international guidelines11)(12 to evaluate environment emissions.

emag is a model that was designed with the objective of evaluating the productive and environmental performance of cattle and sheep systems over one year, and estimating changes over time of the different environmental indicators according to changes in management practices of the system. emag was developed considering principles of:

Ease of use to farmers or their advisors; it is based on easily collected information from inputs that farmers know, or can be readily obtained, otherwise reasonable default values are supplied. The model contains a large database of national research data.

Annual time scale; the model was developed as an annual estimation tool.

Farm scale; the model operates at a farm scale considering different land use and types of pasture. The model has a constraint that it doesn´t track nutrient movement within the farm between paddocks, but it includes nutrients brought in from inputs and losses from the farm system.

Ability to evaluate mitigation options; a range of mitigation scenarios have been added to the model. As well, it provides the user with a set of recommendations to implement mitigation strategies.

The following indicators based on productivity and sustainability were developed:

1. Biophysical production information

animal production (meat and wool)

stocking rate

pasture dry matter production

2. Resource use efficiency

fossil energy use (mj/ha and mj/kg product sold)

nutrients (nitrogen (N) and phosphorus (P)) use and farm nutrient balance (kg N/ha and kg P/ha)

3. Environmental emissions

Greenhouse gases (ghg emissions/ha and per kg product sold)

N & P loss to waterways (kg N/ha and kg P/ha)

2.2 Farmer information required

The model inputs are divided into land use, animal management, farm inputs and fossil energy used in the system.

The total farm area is defined and can be separated into different block areas according to different forage types used. This can account for natural grasslands, natural grasslands oversown with legumes, improved grassland species (as biannual or perennial pastures), annual forage crops, as well as crops for grazing or grain purpose. The soil type for each block area must be defined.

For each introduced forage resource, the model user must either enter the annual dry matter production, or select default values from satellite monitoring for the region13 or from national research information14. The % (by weight) of legume in grassland must be defined by the user or the model can provide default values.

In reference to animal management the model accounts for beef cattle and sheep. For each animal type, the number and category changes (including deaths) during the year are required, as well as the live-weights at the beginning and end of the year, % calving or lambing, and birth weights. Animal purchases, sales and removals (death or eaten) need to be recorded.

For inputs used during the year, information is needed on the type and amounts of fertilizers, supplementary feeds, seeds and agrochemicals. Finally, the direct use of fuel and electricity is required, accounting for transport of animals and inputs, and fuel for energy generation. Machinery activities are entered on an area basis to estimate indirect fuel use.

2.3 How emag works

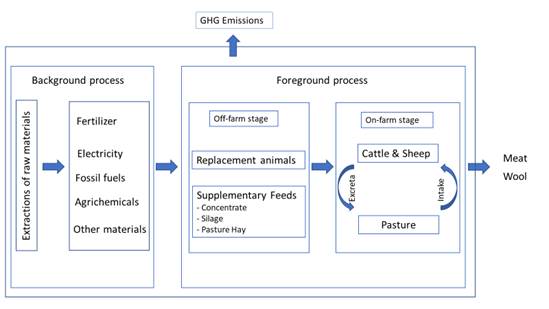

emag methodology for analyzing environmental emissions is based on using life cycle assessment (lca), with the system boundary defined from “cradle-to-farm gate”15. lca is the most appropriate approach to identify the hot-spots within the system and options for innovation and mitigation, as well as to improve the understanding of complex meat systems11)(12. It uses data on farm system and inputs for estimating environmental impacts throughout the life cycle related to a product (beef, sheep meat and wool). Figure 1 shows the various factors included in the ghg estimation in emag.

A critical component evaluating a farm system and environmental emissions is animal feed consumption. Thus, an animal biology model (tier 2) is used to determine dry matter intake (dmi) according to animal category, animal productivity, diet quality and management circumstances.

The equation for estimating dmi for growing and finishing cattle is16:

dmi = bw 0.75 • ((0.2444 . ne ma - 0.0111. ne ma 2 - 0.472)/ ne ma )

Where: dmi = dry matter intake, kg day-1 bw = live body weight, kg nema = estimated dietary net energy concentration of diet, mj/kg

dmi for mature beef cattle is calculated using:

dmi = bw 0.75 • ((0.0119 . ne ma 2 + 0.1938)/ ne ma )

The equation for estimating dmi for sheep(16) is:

dmi = ge/Energy density of the feed

Where: ge is calculated for each animal subcategory17

Energy density of the feed is a default value of 18.45 mj kg-1 of dry matter

Total energy requirements are determined by the model. The energy from supplementary feed is subtracted (accounting for wastage and ne concentration) and the remainder is assumed to be derived from grazing and is apportioned between the different forage types across block areas according to the relative dm production and utilization values in Table 1. In all cases the model assumes different percentages of feed utilization according to different feed types (Table 1). The model may, alternatively, be used with any external or internal feeds that have been supplied to the system (e.g. supplements or concentrates), where the user can provide quality characteristics from the feed. However, in all cases the model assumes same quality between categories.

The feed intake is used to calculate methane from enteric fermentation (using tier 2 ipcc 2006 emission factors), methane from manure management (based on volatile solids calculated using feed digestibility concentration) and ipcc 2006 emission factors11)(12.

The amount of dmi is multiplied by the average nitrogen concentration (percentage nitrogen) of the diet (weighted according to the relative proportions of different feed types in the diet) to get the amount of nitrogen consumed (crude protein/6.25). Nitrogen output that is retained in product(s) (meat, hide, blood and milk) is then subtracted from the nitrogen consumed to calculate the amount of nitrogen excreted and that is linked to ipcc17 emission factors for nitrous oxide (direct and indirect emissions).

The equation for estimating N excreted from cattle and sheep17 is:

kg N excreted = kg N consumed - kg N in products

Indirect nitrous oxide emissions are estimated using leaching and ammonia volatilization emission factors17. Nitrous oxide emissions from crop residues are also estimated, as well as the on-farm direct carbon dioxide emissions from urea fertilizer and lime application based on their composition17.

Table 1: Assumed percentage utilization by animals of different feed inputs

| Feed type | % Utilization* |

|---|---|

| Natural grasslands | 0.50 |

| Natural grasslands oversown legumes | 0.55 |

| Pastures | 0.60 |

| Annual crop feeding | 0.65 |

| Silage | 0.80 |

| Hay | 0,80 |

| Grain/Supplements | 0.90 |

(*) _ based on expert opinion

The presence of housing of animals is not relevant for national cattle systems and the only relevant infrastructure are cattle yards, shearing facilities, wire fencing, etc., so it is assumed that CO2 emissions from infrastructure are negligible following ipcc17 recommendations. In the same way, emissions from machinery, equipment or buildings were excluded based on lack of currently available data and because it is assumed that they have no significant impact18. The off-farm ghg sources considered are embodied emissions for inputs used on the farm. The source of the supplementary feeds brought onto farms is not always known when purchased. Therefore, based on recommendation from Wheeler and others19) and fao12, the embodied emissions for supplementary feeds are based on the rate supplied by the user (in tons) and typical lca-based emission factors (kg CO2 equivalents per kg dm) for growing the feed, plus any manufacturing and transportation required considering average distance (100 km) according to country size (Table 4). In the case of fertilizer a similar process is used, developed from the beef national carbon footprint study20, using an lca study on fertilizer accounting for overseas transport of sourced material used21 and manufacturing and transport in Uruguay (Table 3). To account for animals sourced from off-farm, embodied emissions are difficult to account for since previous animal management is unknown. Thus, to avoid mistake from this source, the ghg product footprint calculation is based on net animal product exported from the system, i.e., subtracting the purchased liveweight11)(12.

The ghg emissions from all sources, covering animal product, feed production, production and use of all inputs, and energy use are then summarized and divided by the farm area to get per-hectare results. For calculation of ghg emissions per kg product, an allocation approach is used. Firstly, where cattle and sheep are grazed together the model allocates emissions between cattle and sheep based on their relative dmi11)(12. In the case of sheep, the total sheep ghg emissions are allocated between lw (liveweight) sold for meat and wool, using the latest methodology from leap11 based on protein mass allocation.

Finally, all ghg emissions are expressed in CO2 equivalent units to account for global warming potential of each gas assuming a 100-year time horizon (25 for CH4, 298 for N2O and 1 for CO2)17.

The fossil energy demand model is estimated from the energy demand of the fossil fuels of the system (38.5 mj/lts diesel, 34,2 mj/lts fuel), electricity demand of the system taking into account the national energy matrix (3.6 mj/kWh), energy demand for manufacturing, and transportation of goods and services used by the system11)(12.

For example, a farm of 200 ha that export 90 kg meat/ha/yr consumes annually 2000 l diesel and 5000 kWh electricity.

Model calculation:

2000 * 38.5 = 77.000 MJ/yr from fuel

5000 * 3.6 = 18.000 MJ/yr from energy consumption

Total fossil energy demand is: 77.000 + 18.000 = 95.000 MJ/yr or 475 MJ/ha/yr or 5.3 MJ/kg meat/yr

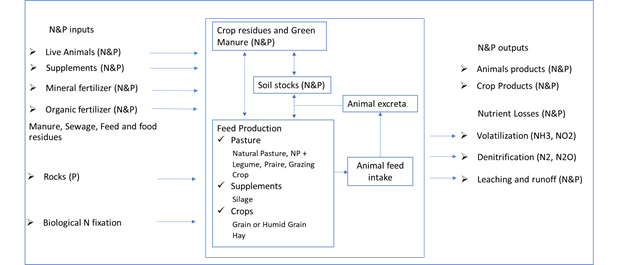

For the nutrient model, external inputs (Figure 1) and outputs (product) of N and P from the system are estimated, as well as potential losses under the different forms of N, and particulate and soluble P (Figure 2).

Calculation of nutrient balances is based on the sum of all outputs (N&P) minus that for inputs, as shown in Figure 2 based on lca methodology. Table 2 represents N&P parameters used by the model. Natural N input from N fixation is calculated from the percentage of legume in forages and the area of land use and dm production22. Atmospheric deposition is calculated directly from the amount of hectares and an annual N deposition factor23. For P inputs related to supplements the same procedure is used as for N, in the case of fertilizer it is converted from P2O5 content (tons) into P. For the N&P output account, it uses the content of each nutrient in meat sold or eaten, and wool produced by the system. Farm P emissions are dominated by runoff of soil-P, as calculated by a country-specific tier-2 model24. This was based on 0.47 kgP/ha of particulate-P from erosion (1 ton ha/yr) using a country-specific erosion model25 and 0.36 kg P/ha of dissolved-P, where 0.06 are losses from the soil (3 ppm P Bray I).

For some feed parameters, the model provides national research information for cases where information is not available (e.g. annual average dry matter production, pasture quality, percentage of legume or quality of supplements). The environmental burden (energy, ghg and nutrients) from the production of inputs is provided based on national information and default values from research in case of lack of information (Table 3).

Table 3: Type of fertilizer used and their environmental embodied emissions

| Fertilizer (N-P-K-S) | Energy (MJ/kg) | GHG (CO2e/kg) | N (% by weight) | P2O5 (% by weight) |

|---|---|---|---|---|

| 7-0-40-020)(21 | 10.10 | 0.79 | 7 | 40 |

| Diammonium phosphate20)(21 | 10.10 | 0.79 | 18 | 46 |

| Monoammonium phosphate20)(21 | 10.10 | 0.75 | 12 | 52 |

| Phosphate rock20)(21 | 3.00 | 0.24 | -- | 28 |

| Superphosphate20)(21 | 5.58 | 0.37 | -- | 18 |

| Urea20)(21 | 22.55 | 0.79 | 46 | --- |

Table 4: Supplement feeds and their environmental embodied emissions

| Supplements feed | Energy (MJ/kg) | GHG (CO2e/kg) | N % | P % |

|---|---|---|---|---|

| Wheat Bran14)(29 | 5.70 | 0.12* | 2.75 | 0.68 |

| Rice Bran14)(29 | 5.70 | 0.03* | 2.43 | 1.12 |

| Sunflower expeller14)(29 | 5.70 | 0.83* | 5.80 | 0.83 |

| Soybean expeller14)(29 | 5.70 | 0.17* | 7.31 | 0.43 |

| Concentrate (adult animals)14)(20)(29 | 5.20 | 0.12* | 1.92 | 0.10 |

| Concentrate (young animals)14)(20)(29 | 5.20 | 0.12* | 2.40 | 0.10 |

| Concentrate (calves)14)(20)(29 | 6.40 | 0.17* | 2.88 | 0.74 |

| Lucerne hay14)(29 | 0.58 | 0.01* | 3.01 | 0.24 |

| Low quality hay14)(20)(29 | 1.36 | 0.01* | 0.64 | 0.07 |

| Pasture hay14)(29 | 0.58 | 0.01* | 1.62 | 0.19 |

| Maize grain14)(29 | 0.90 | 0.17* | 1.44 | 0.25 |

| Sorghum grain14)(29 | 1.00 | 0.07* | 1.38 | 0.30 |

| Maize humid grain14)(20)(29 | 1.35 | 0.06* | 1.33 | 0.21 |

| Maize silage14)(29 | 0.36 | 0.09* | 1.26 | 0.17 |

(*) _ Data from ghg emissions obtained from modelling each supplement production through the tool.

2.5 Internal parameters

Animal ghg emissions are calculated using emission factors, primarily from national research and default Intergovernmental Panel on Climate Change (ipcc) values where there is a lack of information. In the case of enteric methane emissions from beef cattle, 6,5% (CH4 conversion factor) is used according to Dini and others31)(32 and Orcasberro and others33. For ghg emissions from supplement production, data is provided from previous national research from the Agriculture Ministry beef carbon footprint study20. For fossil energy use, parameters are based on national information, 2,98 kg CO2e/lt fuel and for electricity the national energy matrix (3% from fossil energy) is considered34. For machinery use on farm, fossil fuel consumption for each operation data recommended from Uruguayan Chamber of Agricultural Services is used35. Energy parameters from fertilizer manufacturing are used based on nz research database21, whereas for supplements production national research is used29.

2.6 Quality of the different pastures and forages

Cattle and sheep production in Uruguay are largely associated with extensive grazing systems on unique natural grassland systems of relatively poor feed quality and often with no nutrient inputs in fertilizer. In the following table (Table 7) there are representative default values for the quality of the different pastures and forages unique for Uruguay - including digestibility, crude protein, me and P concentrations.

Table 7 Quality of pastures and forages

| Type of Pastures and Forages | Digestibility % | Crude Protein % | ME Mcal/kg DM | P conc. % |

|---|---|---|---|---|

| NG Areniscas ladera alta36)(37 | 52,58 | 8,03 | 2,10 | 0,15 |

| NG Areniscas bajo36)(37 | 52,58 | 6,22 | 2,10 | 0,12 |

| NG Basalto medio38)(39 | 55,80 | 8,03 | 2,10 | 0,14 |

| NG Basalto profundo38)(39 | 55,80 | 9,43 | 2,10 | 0,14 |

| NG Basalto superficial negro38)(39 | 55,80 | 8,03 | 2,10 | 0,14 |

| NG Basalto superficial rojo38)(39 | 55,80 | 8,03 | 2,10 | 0,14 |

| NG Cristalino profundo40 | 51,20 | 8,60 | 2,10 | 0,13 |

| NG Lomadas este41 | 52,0 | 8,80 | 2,10 | 0,15 |

| NG + LS40)(42 | 57,40 | 12,35 | 2,20 | 0,30 |

| NG + WC + LC40)(42 | 59,30 | 13,23 | 2,20 | 0,30 |

| Lucerne43 | 65,60 | 23,30 | 2,50 | 0,24 |

| Oat38)(44 | 72,60 | 16,73 | 2,50 | 0,22 |

| Ryegrass38)(44 | 72,60 | 18,50 | 2,70 | 0,30 |

| Maize forage45 | 62,00 | 8,99 | 2,30 | 0,30 |

| Sorghum forage45 | 62,00 | 8,99 | 1,80 | 0,30 |

| Wheat forage45 | 72,00 | 17,60 | 2,30 | 0,26 |

| Chicori + RC45 | 65,60 | 33,60 | 2,60 | 0,25 |

| WC+LC+F pasture45 | 70,00 | 18,10 | 2,40 | 0,31 |

| Oat +Ry + RC45 | 72,00 | 17,60 | 2,60 | 0,26 |

| WC+LC+Ry pasture43 | 70,00 | 18,10 | 2,40 | 0,31 |

| Lucerne silage14 | 51,71 | 18,32 | 2,3 | 0,27 |

| Maize silage14 | 66,29 | 7,30 | 2,38 | 0,21 |

| Sorghum silage14 | 58,26 | 7,55 | 2,20 | 0,18 |

| Moha hay14 | 59,79 | 12,66 | 2,35 | 0,19 |

NG_Natural grassland, LS_Lotus Subiflorus, LC_Lotus Corniculatus, WC_White clover, RC_Red clover, Ry_Ryegrass, F_Fescue

2.7 emag validation process

To validate emag model two published studies with very good data were selected46)(47 . The New Zealand study referred to a New Zealand typical system, of beef and sheep on hill country land46. The published data make reference to a survey from North Island hill country which makes up about a third of New Zealand beef production. To estimate environmental outputs, the Overseer model was used9. The second study referred to a Canadian cow-calf dryland prairie farm where steers and heifers are fattened on high-grain diets in a feedlot47. This production system is representative of western Canada beef farms. More than 75% of Canada cow herd and feedlot cattle are in the four western provinces. To estimate ghg from this system the holos model was used10. Those country models had been validated against research within their own countries.

The New Zealand published data was entered into the emag model and the outputs were compared to the published ones. emag and Overseer outputs were very similar in terms of energy and nutrients with just a slightly difference in ghg/ha and ghg emission intensity, probably because of pasture quality (Supplementary tables. S1). Canadian data were also entered into emag and Overseer and the outputs of the three models were compared. A good agreement was found on ghg/ha and ghg emission intensity between the three models. Nutrients and energy outputs were not available for the published study, so it was not possible to make that comparison (Supplementary tables. S2).

The comparisons made reflected that emag is a robust model that could be used to estimate environmental outputs of beef and sheep systems.

3. Results and discussion

3.1 Case study

The case study used is an extensive system of mixed (cattle and sheep) breeding, characterized by year-round mating (spring, summer and winter), low pregnancy rate and cull cows sold in low condition. The farm has a high proportion of the area composed of shallow basalt soils.

Table 8 shows the characteristics of the system and management practices that were used at the beginning of the project (baseline) and at the end of it. At the beginning of the project the system had 88% of the area in natural grasslands and 12% with improvements of natural grasslands with legume (Lotus subiflorus). It had excessive use of supplements feed (wheat bran, lucerne hay, sorghum grain and 16% of crude protein concentrate) and minerals, at a rate of 73 kg/ha/year. The goal pursued by the producer was to promote an improvement in productivity while taking care of the environment. This included the efficient use of resources without modifying or reducing the input/output ratio. At the end of the project, a restricted spring-summer mating system was established, the whole area of legumes was increased up to 17% of total land and the use of supplements was reduced by almost 35% during the year.

Table 8: Summary of the change in management over time in the case study farm. Start year was 2014/2015, while the project ended in 2016/2017.

| Management practice | Year 2014/15 | Year 2016/17 |

|---|---|---|

| Land use_(%) | NG (88), NG+LS (12) | NG (83), NG+LS (12), NG+LP (5) |

| Supplements use (kg/ha/yr) | 77 | 48 |

| Stocking rate (LU/ha/yr) | 0,7 | 0,65 |

| Fertilizer inputs (tonnes/yr)* | 1.05 | 1.7 |

| Grazing practices | No grazing plan | Feed budgeting used |

| Husbandry practices | Without mating control | Spring-summer mating |

| Sell cull cows after weaning | Fattening cull cows | |

| 3-4 yr old cows at first calving | 3 yr old cows at first calving |

NG_Natural grassland, LS_Lotus subiflorus, LP_ Lotus pedunculatus LU_Livestock unit (based on an adult cow of 380 kg LW that weans one calf per year). (*)_ Fertilizer was used only on lotus pasture area, in 14/15 was 1 ton of 7-0-40-0 and 0.05 ton of diammonium phosphate and in 16/17 was 1.7 tonnes of 7-0-40-0.

At the end of the study in 2016/2017, meat production (cattle and sheep) had stabilized at an additional 25% compared to 2014/2015. This was associated with an adjustment in stocking rate according to dm production, which resulted in better cow pregnancy and fattening of cull cows. Regarding outputs from emag, Table 9 shows a reduction in nitrogen losses, although the use of fertilizer has increased. This is probably explained due to an improvement in the use efficiency and reduction in stocking rate, meaning less N excreted by animals, which is the main source of N losses. In the case of P, the high negative balance is explained due to low inputs to the system, with increases of meat production making the balance of the system even more negative. This would indicate a system with possible slow mining of fertility (at least for phosphorus) which could affect long-term sustainability.

Table 9: Result of the use of emag and changes in the indicators from the production system

| Year 2014/15 | Year 2016/17 | |||

| Calf weaning rate (%) | 73 | 76 | ||

| Lambing rate (%) | 94 | 113 | ||

| Meat production (kg/ha) | 92 | 119 | ||

| GHG emissions (CO2e/ha) | 1447 | 1198 | ||

| CH4 (%) | 78,5 | 77,0 | ||

| N2O (%) | 19,1 | 19,4 | ||

| CO2 (%) | 1,7 | 2,6 | ||

| Meat emissions (kg CO2e/kg meat) | 15,7 | 11,5 | ||

| Wool emissions (kg CO2e/kg wool) | 20 | 19 | ||

| Fossil energy use (MJ/kg meat) | 7,9 | 3,5 | ||

| N | P | N | P | |

| Nutrient balance (kg/ha) | 9,2 | -0,23 | 9,6 | -0,66 |

| Nutrient losses (kg/ha) | 10,6 (*) | 0,52 (**) | 8,2 | 0,53 |

(*) _ For N is leaching and gaseous losses, (**) _For P is runoff

In the case of energy intensity, there was an improvement in the energy use efficiency and a reduction in the use of non-renewable fossil energy, explained by the decrease in the use of imported supplements, with their associated embodied energy and the higher production of meat per hectare. There was a significant reduction in total ghg emissions/ha, caused by the reduced stocking rate and lower environmental embodied emissions from the inputs due to less use of the supplement (emission from transport and processing). The outstanding result is that together with the increase recorded in meat production/ha (29%), there was a reduction in the emissions intensity by more than 40%.

In the case of nutrient balance, there is evidence of low N and P inputs, outputs (in meat & wool), however in case of P the results indicate some mining of P which could slowly deplete fertility.

3.2 Model discussion

This model was developed as a decision support system to be used for cattle and sheep farmers and advisors as an indication of their resource use and environmental emissions. The focus of the model is on providing an estimate of on-farm potential environmental impacts based on farm-specific inputs and outputs. Although emag provides a holistic approach to farm-scale assessment of the effect of management practices on farm-average environmental losses, it has the constraint that it does not provide environmental information specifically for the individual blocks within the farm. However, the model has the ability to account for differences in land use, inputs, production and management between blocks within the farm.

The model considers feed data from diverse types of land and feed resources used for cattle and sheep production. It accounts for different type of pastures (e.g. natural pastures from different regions of the country, mix of forage species or legume oversown in natural pastures) and a wide range of supplementary feeds. If the user is lacking some specific feed information for the farm system, the model has default values that can be selected. Where natural pasture represents the major resource used for feeding animals, the quantity and quality of information is a key aspect which is particularly important for Uruguay. Therefore, the model provides options for using pasture production estimated from national research information from different regions, or dry matter production from satellite monitoring. This information is provided by the ipa through the lart project48. The system uses satellite information translated into forage production taking into account different types of pasture, weather conditions and eco-physiological factors49. Pasture quality information is more difficult to determine, especially considering changes between seasons, and default average values can be selected. However, in all cases this is likely to be underestimated because animal selection during grazing probably results in higher quality values for actual intake50.

emag produces a range of production and environmental indicators. Both are connected through the calculation of environmental intensity indicators, for example, for ghg emissions per kg of meat exported from the system. This requires that the model calculates production indices based on the animal input information that the user provides on an annual basis. However, when the user wants to develop scenarios through implementation of technologies, they need to make an assumption about the likely impact on production in the model.

Methane emissions represent the greatest contributor to whole ghg emissions from cattle systems, representing about 75%6, and the emission intensity by product is higher for extensive systems than intensive systems51. The majority is provided from enteric fermentation and is relatively high due to low digestibility of natural pasture during the year than for introduced pastures. Digestibility affects the calculated intake value, which has a large effect on enteric methane emission and can have a significant effect on the total system ghg emissions. Methane emissions from dung during grazing is included17, but the contribution to overall methane production is minor.

Related to the ghg indicator, the model currently ignores C sinks and the contribution of changes in on-farm C stocks (soil, pasture, or forest on farm) to on-farm ghg emissions. However, international agreement on how to account for some of this is lacking. Embodied CO2 emissions and fossil energy demand from the production of inputs were included in the model to indicate the impacts from all the input emissions linked to farm production and on-farm activities. The values for these embodied emissions are now based on relatively old data20. Although updated values are not available, it is probable that modernization and efficiency gains within the processing industry would suggest that the values used are probably overestimating the processing contribution.

In the case of natural N inputs as atmospheric deposition, the model uses the unique information provided from national research23. This is important since it is often the main N input in animal systems (e.g. breeding systems) in Uruguay, where the main forage resource is natural pastures and where commonly no mineral fertilizer is applied, and the very low percentage of natural legume determines low N fixation. There is a possible minor contribution of N2 fixation from free-living microorganisms, however following leap guideline to not be included in accounting for N flows unless published local data are available. This has a relatively large effect on the calculated N balance, as shown in the case farm study. This study also showed a small negative P balance, suggesting that the farm is mining its soil P reserves. However, there is uncertainty around the P index in the model that is used to estimate P losses from the system. More research is needed to provide better data for more accurate calculation of P losses and the P balance in the future. In the model, a key input that the user needs to provide is P content in the soil, which is not easy to obtain and could change between blocks with different management.

emag provides environmental emissions results on a per-hectare basis -which is particularly relevant for nutrient losses to water- as well as on a per-kg product basis. The latter is useful for producers/processors/marketers. For the nutrient balance, the tool is valuable to identify whether a system is mining soil P and/or N as an indication of long-term sustainability. Similarly, the fossil energy use efficiency provides a guide to level of depletion of a key non-renewable resource.

In summary, emag provides a holistic approach to farm-scale assessment of the effect of management practices on environmental losses. It is an evolving model, with ongoing improvement in output predictions and addition of new mitigation options as more research is generated. For example, it is possible to include indicators of other resource use (including for off-farm land, such as where you have cattle supplementation with brought-in feeds) or pesticide use.

4. Conclusion

Cattle and sheep systems in Uruguay and worldwide are challenged to reduce their environmental footprint while increasing efficiency and production. To achieve this challenge, user-friendly tools are needed that can translate research findings into practical information that could improve decision making by farmers and advise different stakeholders. emag is an innovative “Uruguay-specific” model that can provide information for the national cattle and sheep sectors to quantity key indicators of importance at global and local scales.

This model meets the current methodology requirements according to international guidelines11)(12)(52) to evaluate environment emissions. It could be used to assist the national cattle and sheep sector to be aligned to Uruguayan international commitments and markets. However, Uruguay still needs to continue working and evolving its farm systems toward the implementation of sustainable practices, and emag could be a support for achieving this.