1. Introduction

Most of the plums produced in the valleys of Río Negro and Neuquén (Argentina) are stored at low temperatures in order to extend the window of sale in the domestic market or to withstand the transport period to distant counter-market. Harvesting the fruits in their optimal stage of maturity is one of the determining factors of the final quality of the product1. However, the logistics of the harvest are complex, and part of the fruit is harvested with an advanced maturity stage (more than the recommended for storage).

1-Methylcyclopropene (1-mcp) has shown to be effective in reducing the ethylene production rate and consequently softening, acidity loss, and epidermis color changes in different plum cultivars2)(3. The effectiveness of this treatment depends on the stage of maturity of the fruits at which it is applied, and it has been observed in various species that the more mature the fruit is, the lower the response to treatment with 1- mcp4. The aim of this trial was to determine the efficiency of treatment with 0.4 µL L-1 of 1- mcp in Larry Ann plums harvested in four different stages of maturity.

2. Materials and methods

Larry Ann plums (Prunus salicina L) were harvested from a commercial orchard in Río Negro (Argentina), at 4 maturity stages: maturity 1 (M1, ~62 N), maturity 2 (M2, ~58 N), maturity 3 (M3, ~50 N) and maturity 4 (M4, ~35 N).

After each harvest, the fruits were taken to the laboratory and maturity indexes were determined on 3 repetitions of 20 fruit each. Fruits were divided into two homogeneous lots: treated with 0 (Untreated control) or 0.40 µL L-1 of 1-mcp (Treated) for 24 hours during fruit-cooling. Subsequently, fruits were stored at 0 ºC and 90% of relative humidity for 30, 40 and 50 days and evaluated immediately after removal from the chamber, and after 3 and 7 days of shelf life at 20 ºC on 3 replicates of 20 fruit each.

Ethylene production rate (µL kg-1 h-1) was determined on 3 repetitions of 6 fruits right after harvest and after removal from cold storage, for up to 20 days at 20 ºC or until reaching the climacteric peak. The fruits were weighed and enclosed in 3-L jars for 30 min at 20 ºC, and then 1 mL sample was extracted from the headspace. The sample was analyzed with a gas chromatograph (gc-14A, Shimadzu, Japan) equipped with an alumina column (40 ºC) and a fid detector (210 ºC). Helium was used as gas carrier.

Flesh firmness (ff) was determined with an electronic fruit texture analyzer (fta-gs14, Güss, South Africa) with an 8 mm-diameter probe and expressed in Newtons. Sections of skin were removed at the widest point of the fruit on opposite sides to determine ff. Two slices of flesh were taken from each fruit and juiced to determine soluble solids content (ssc) with a digital refractometer (pal-1, Atago, Japan) expressed as %, and titratable acidity (ta) (%) by titration of 10 mL of juice with 0.1 N NaOH to a pH of 8.2, which is expressed as a percentage of malic acid.

Epidermis color was determined visually as color coverage (%) and with a tristimulus colorimeter (cr-300, Minolta, Japan) on two well-colored areas on each fruit after removing the epicuticular wax. Data are expressed in coordinates L*, Chroma, (a2 +b2)1/2, and Hue (tan−1 (b/a)).

Flesh color and chilling injury (ci) development were assessed visually by cutting each fruit on half along the equatorial axis. A four-grade visual scale according to the percentage of flesh colored or injured was used: Uninjured (0%), G1 (up to 25%), G2 (25-50%), G3 (50-75%) and G4 (75-100%). Intensity of coloration and severity of ci were calculated as the total number of fruit in each grade multiplied by the grade and divided by the total of injured fruit. Chilling injury was also expressed as percentage of affected fruits.

Data were subjected to analysis of variance (Anova) using Infostat5. The separation of means was performed using Tukey test with a significance level of 0.05 (p-values).

3. Results and discussion

3.1 Harvest evaluations

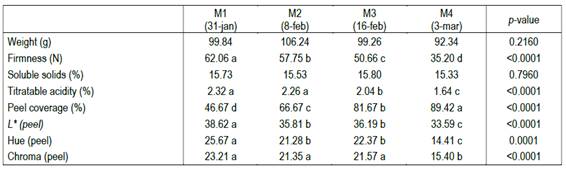

Ethylene production rate at 20 ºC during ripening after harvest differed significantly between harvest dates (Figure 1). As the harvest was delayed, the time required to start the ethylene production and to reach the climacteric peak was reduced.

Figure 1: Ethylene production rate of Larry Ann plums during shelf life at 20 ºC after harvest on 4 different maturity stages: M1 ((), M2 ((), M3 (() and M4 (()

Other authors also observed that fruits harvested with more advanced maturity initiated ethylene production before those harvested earlier6. In other words, as harvest is delayed, the fruits are closer to reaching their climacteric maximum and consequently their deterioration, which reduces their storage potential.

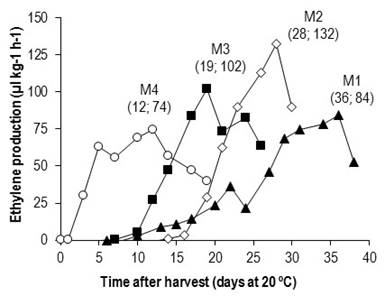

Flesh firmness values decreased as harvest was delayed, showing significant differences between harvest dates (Table 1). The softening rate also increased with delayed harvest, being lower from the M1 to M2 stage (~ 0.6 N / day) than from the M2 to M3 stage (~ 1 N / day) or from M3 to M4 (2,2 N/day). Titratable acidity decreased significantly from 2.3% to 1.6%, thus increasing the ssc/ta ratio. As the harvest was delayed, an increase in the percentage of color coverage and a darkening of epidermis color (decrease in L* and Hue) was observed (Table 1).

3.2 Storage evaluations

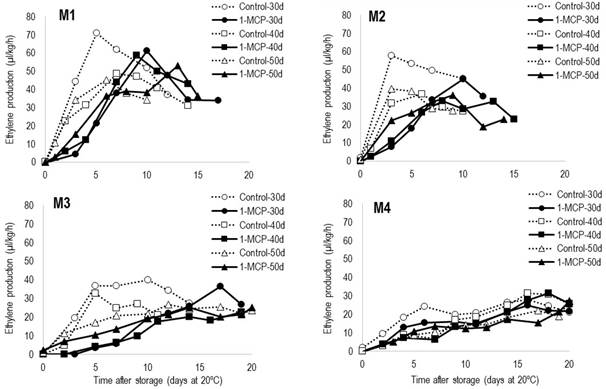

In the evaluations immediately after cold storage, ethylene production rate was undetectable in both control and 1-mcp treated fruits for all harvest dates and at all storage times. However, ethylene production increased during the shelf life period showing clear differences between treatments, harvest dates and storage times. 1-mcp delayed ethylene production after 30, 40 and 50 days of storage in fruit harvested with M1 and M2 (Figure 2, M1 and M2). In fruit harvested with M3 it was only effective after 30 and 40 days (Figure 2, M3), while for M4 fruits there were no differences at any storage period (Figure 2, M4). As storage was extended and harvest was delayed, the ethylene production curves flattened, the climacteric peak was weaker and the differences between control and treated fruit were lost (Figure 2). The reduction in ethylene production due to treatment with 1- mcp has been attributed to a decrease in the activity of the enzymes involved in ethylene biosynthesis (acs and aco) and to a lower accumulation of acc7.

Figure 2: Ethylene production rate of control and 1- mcp treated Larry Ann plums harvested on 31-jan (M1), 8-feb (M2), 16-feb (M3) and 3-mar (M4) during shelf life at 20 ºC after 30, 40 or 50 days of cold storage

The effect on ethylene production rate was manifested in a delay in ripening associated with the maintenance of flesh firmness, acidity and epidermis color, mainly in early harvested fruits and after short storage periods.

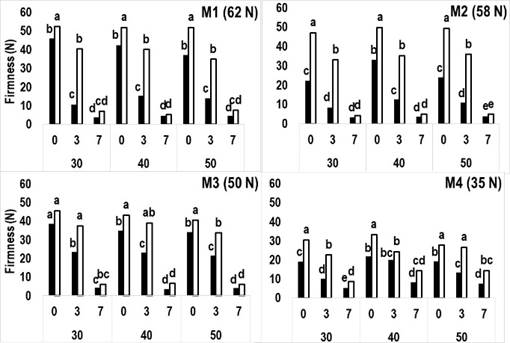

Flesh softening was significantly lower in treated fruits than in control fruits of all the harvest dates, both when removed from the cold storage chamber and after 3 days of shelf life (Figure 2). Firmness is related to the sensitivity of the fruit to mechanical damage, which is an important cause of discard in plums and favors the incidence of rot8. Some authors recommend that the firmness for handling and marketing plums should not be less than 13 N9. Considering this reference value, only fruits treated with 1-mcp maintained recommended values for handling during more than 3 days at 20 ºC (Figure 2). Firmness is also related to the organoleptic quality of plums. The optimum quality of consumption is considered to be reached when the flesh firmness values are between 8 and 15 N for soft pulp plums10, such as Larry Ann. In this work, control fruits reached firmness values for consumption at 3 days of shelf life at 20 ºC, while fruits treated with 1-mcp maintained values between 23 and 40 N, allowing to extend shelf life of the fruits irrespective of the harvest date (Figure 3).

Figure 3: Flesh firmness (N) in untreated control fruits (() and treated with 1-mcp (() of Larry Ann plums harvested in different maturation stages (M1, M2, M3 and M4), kept during 30, 40 or 50 days of cold storage period at 0 ºC, and exposed to different lengths of shelf life (0, 3 and 7 days)

The acids and sugars content are directly related to the flavor of the fruits11. The treatment with 1-mcp maintained higher ta values, mainly in the fruits of M1 and M2, although the differences were not as significant as those observed for flesh firmness values (data not shown). ssc varied inconsistently throughout storage and, in general, higher values were observed in the M4 stage (15.3 - 17.2%) than in M3 (14.1 - 16.1%) or M2 (14.4 - 16%), and higher in these than in M1 (13.4 - 15.5%), without showing significant differences between untreated control and treated fruit.

The development of chilling injury symptoms did not limit the storage of the fruits in any of the evaluations done. Flesh translucency was the most frequently observed symptom and affected between 5% and 30% of the fruits harvested in M1 and M3 (data not shown). The severity of the symptom remained below grade 2, without limiting the commercial quality of the control or 1-mcp treated fruits. Internal browning was only observed after long periods of storage and shelf life, mainly in the untreated control fruits of the first harvest.

4. Conclusions

The treatment with 1-mcp was effective in reducing the ripening rate, where the duration of this effect and the number of parameters affected decreased as harvest was delayed.

In early harvested fruit (~62 N and ~58 N) 1-mcp reduced ethylene production, softening, loss of acidity and darkening of the epidermis, mainly in the shorter storage periods.

In fruits from intermediate maturity (~50 N) 1-mcp delayed ethylene production during shelf life after 30 and 40 days of storage at 0 ºC, and maintained higher flesh firmness values.

In fruit from late harvest (~35 N) treatment with 1-mcp only reduced the loss of flesh firmness, but that was enough to extend both the storage period and fruit shelf life.

Both control and treated fruits reached the flesh firmness for consumption.